In the vanguard of a new technological epoch, 3D Printing emerges as a beacon of innovation, bringing transformative advancements across myriad sectors. From the bustling factory floors to the quiet corners of a hobbyist's workshop, 3D Printing, also known as additive manufacturing, is reshaping the landscape of production and design. As we forge ahead into a future teeming with potential, it behooves us to pause and explore the multifaceted benefits this remarkable technology bestows upon contemporary society.

Imagine a world where intricate creations leap from the drawing board to reality with unprecedented ease, where customization is not a luxury but a norm, and where the global footprint of production markedly decreases.

In this blog post, we will explore the benefits of 3D Printing—a tool that stands as a testament to human innovation, bridging gaps between imagination and tangible realization and fostering a new era of sustainable and personalized production. Join us as we delve deep into the captivating world of 3D Printing- a realm where dreams are not confined to the mind but find form and function in the physical world, heralding unparalleled opportunities for

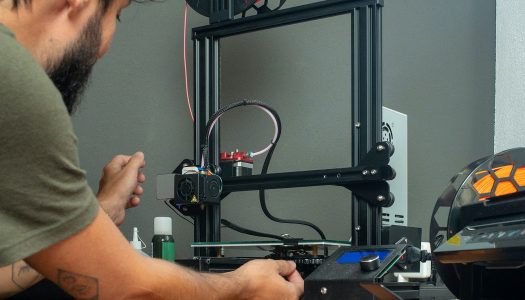

In a world where technological advancement is ceaseless, 3D Printing is a pillar of the modern manufacturing revolution. At its core, 3D printing, or additive manufacturing, is a process that involves layering materials, typically plastics, metals, or ceramics, meticulously to fabricate objects from digital models. These digital blueprints can be crafted using a variety of software platforms, from simplistic applications for casual enthusiasts to sophisticated tools embraced by engineers and designers.

This burgeoning technology, which once graced only the realms of science fiction, is now accessible to individuals and businesses alike, enabling a democratization of manufacturing unseen in previous eras. What sets 3D Printing or additive manufacturing apart from traditional manufacturing is its ability to seamlessly translate digital designs into physical objects, bypassing the need for complex machinery or tooling that might once have been required. This manufacturing process introduces a radical shift in production dynamics, creating a platform where design intricacies and customization are not bound by the same limitations as conventional methods.

Moreover, 3D Printing invites us into an ecosystem where iterative developments are encouraged and often necessary, giving birth to a generation of continually refined and perfected products. As we stand at the threshold of this exciting frontier, it is essential to fully grasp the intricacies of 3D Printing, a realm that promises to redefine our understanding of creation and production in the future.

What are the Pros of 3D Printing?

Check out the many benefits 3D Printing offers in detail here.

Production on Demand

In an age where efficiency and immediacy are prized, 3D Printing is a harbinger of a new epoch where production on demand is feasible and incredibly efficient. As traditional manufacturing often requires long lead times and substantial initial investments, the revolutionary approach of additive manufacturing to production stands as a stark contrast. It facilitates the creation of goods exactly when and where they are needed, significantly reducing warehousing costs and minimizing overproduction. This real-time manufacturing possibility ushers in a nuanced era where businesses can react swiftly to market demands, adjusting production volumes with agility and precision.

Moreover, 3D Printing opens up new avenues for personalization, allowing for a seamless integration of individual customizations without hampering the production process. This shift towards a more responsive and adaptable production model heralds a future where manufacturing is intricately aligned with the actual, immediate demands of the market.

Provides Faster Prototyping

The genesis of any product lies in its prototype, a crucial stage where ideas transition from concept to tangible form. 3D Printing has considerably expedited prototyping, serving as a catalyst in the product development cycle. Designers and engineers can now iterate prototypes within a fraction of the time traditional methods require, fostering a dynamic environment where improvements can be implemented rapidly. This swift prototyping is a matter of convenience and a significant competitive advantage in a market that values speed and adaptability.

With 3D Printing, businesses can swiftly maneuver through the development phase, making real-time adjustments based on tangible data and observations. The additive manufacturing process enhances the final product's quality and ensures a more fluid and responsive development trajectory, positioning businesses at the forefront of innovation and market responsiveness. So, investing in a 3D printer is a wise move.

Eco-Friendly

In an era where sustainability is no longer a choice but a necessity, 3D Printing emerges as a technology aligning with the global efforts to reduce environmental impacts. Traditional manufacturing methods often involve considerable waste, as materials are cut away to create the final product. In contrast, 3D Printing, being an additive manufacturing process, uses materials more efficiently, layering them precisely where needed and minimizing waste.

Furthermore, the potential to produce goods locally reduces the transportation carbon footprint, as products no longer need to traverse long distances from factory to consumer. As businesses and consumers alike grow more conscious of the ecological footprint of products, the adoption of 3D Printing stands as a testament to a collective move towards more sustainable production practices, championing a future where technology and ecology walk hand in hand in harmony.

Fast Design and Production

Navigating the ever-evolving labyrinth of technology and consumer expectations, 3D Printing offers a beacon of hope with its fast design and production potential. This pioneering technology facilitates a seamless workflow, where the transition from design to production is swift and devoid of numerous traditional stumbling blocks. Artists, architects, and designers can witness their visions morphing from digital blueprints to physical realities within hours, fostering a climate of innovation and expediency.

This brisk pace is not confined to the domain of prototypes but extends to the final products, thus significantly reducing the time-to-market. In a world that thirsts for rapid innovation and immediate gratification, the swiftness of 3D Printing in bringing designs to life stands as a monumental leap forward, paving the way for a future where creativity meets immediacy, ushering in a new era of production where time is no longer a constraining factor.

Best For Complex Geometries

In the grand tapestry of manufacturing, the advent of 3D Printing heralds a time where complexity in design is not a hindrance but a celebrated attribute. Traditional manufacturing methods often find themselves constrained when it comes to creating intricate and complex geometries, but 3D Printing thrives in this arena, offering an avenue where complexity does not translate to increased costs or production time.

This technology, with its layer-by-layer approach, allows for the fabrication of structures that were once deemed impossible or highly impractical. From intricate lattice structures to complex organic forms, 3D Printing embraces complexity with grace and efficiency. This freedom unleashes a wave of innovation in various fields, including aerospace, architecture, and healthcare, where complex, customized, and optimized structures can now be created with relative ease.

By championing complex geometries, 3D Printing opens up a realm of possibilities, driving a renaissance in design and manufacturing where the only limit is the extent of one's imagination. So, buy 3D printers online and check their enormous capabilities.

Cost Effective Manufacturing Proces

In an economic landscape where judicious utilization of resources is key to sustainability, 3D printing steps forward as a cost-effective solution in the manufacturing arena. Traditional manufacturing often entails hefty initial expenses, including the creation of molds and the setup of production lines, especially for small-batch productions. However, 3D Printing negates the necessity for these preliminary investments, offering a pathway to cost savings particularly noticeable in short-run productions and prototypes.

Moreover, the precision that comes with this technology minimizes waste material, further driving down costs. Businesses can now venture into creating specialized, customized products without the looming fear of exorbitant expenses, fostering an environment where innovation doesn't have to come at a premium. As we navigate deeper into an era of economic prudence, 3D Printing stands as a beacon of cost-effective manufacturing, transforming production landscapes and making innovation accessible to all.

Produces Strong and Lightweight Parts

As industries evolve, the demand for components that marry strength with lightness has surged, a need that 3D Printing adeptly addresses. This technology has the capability to produce parts with complex internal structures, such as honeycombs or lattices, which retain strength while shedding unnecessary weight. Particularly in sectors where the balance between weight and strength is critical, 3D Printing emerges as an indispensable tool. These optimized structures, often impossible or extremely difficult to create using traditional methods, not only enhance performance but also contribute to energy efficiency, a trait highly sought in modern manufacturing.

Furthermore, the versatility in material choices, including high-strength alloys and composites, grants designers the freedom to engineer products that precisely meet specific strength and weight criteria. As we stand at the cusp of a manufacturing revolution, 3D Printing heralds a future where strong, lightweight parts are not an aspiration but a tangible, accessible reality. With a professional printer service and quality parts, you can create durable parts that last long.

Enhance Creativity and Innovation

In a world where the boundaries of creativity are continually being stretched, 3D Printing emerges as a luminary, fostering an environment where innovation thrives unfettered. This revolutionary technology breaks the shackles of traditional manufacturing constraints, allowing artists, designers, and inventors to explore realms previously deemed unreachable. The possibilities for customization are virtually endless, enabling individuals to infuse a personal touch into their creations, ushering in a golden era of bespoke products.

Moreover, 3D Printing grants a tangible form to abstract concepts quickly, allowing for swift feedback and iterations, a crucial aspect in the evolutionary process of design. It encourages a bold foray into the unknown, nurturing a culture where creativity is not hampered by logistical limitations. As we venture into a future rich with potential, 3D Printing stands as a catalyst, driving a renaissance of creativity and innovation, where dreams are molded with precision, imagination meets reality, and the canvas of invention is boundless.

Educational Tool

As education embarks on a journey towards more interactive and experiential learning, 3D Printing asserts itself as a potent tool in the educational arsenal. This technology has the power to bring abstract concepts to life, offering students a tangible connection to theories and ideas, thus fostering a deeper understanding and engagement. From visualizing complex geometric shapes to creating replicas of historical artifacts, 3D Printing adds a dynamic, hands-on component to learning environments.

Moreover, it cultivates a spirit of inquiry and innovation among students, encouraging them to design, create, and iterate, honing skills that are quintessential in the modern world. By integrating 3D Printing into the educational framework, we pave the way for a generation of thinkers, creators, and innovators adept at navigating the complexities of a rapidly evolving world. As we stand on the threshold of an educational revolution, 3D Printing beckons us into a future where learning transcends textbooks, fostering a rich, immersive, and empowering educational journey. So, buy printers online and understand the concepts better.

Less Waste Than Traditional Manufacturing Methods

In a time where sustainability is not just encouraged but imperative, 3D printing steps forth as a beacon of responsible manufacturing, championing the significant reduction of waste materials. Traditional manufacturing techniques often involve subtractive manufacturing methods where large amounts of raw materials are removed to carve out the desired product. 3D Printing follows additive manufacturing processes, wherein the material is deposited only where necessary, essentially fabricating objects layer by meticulous layer. This nuanced approach not only conserves materials but also allows for the utilization of recycled or biodegradable materials, contributing to a greener manufacturing cycle.

As businesses and consumers alike gravitate towards more environmentally conscious choices, the adoption of 3D printing manufacturing technologies manifests as a step towards a future where production harmonizes with preservation, fostering a world where innovation walks hand-in-hand with sustainability, guiding us towards a future that honors both progress and the planet. With so many 3D printer benefits, incorporating it into business is a feasible and profitable step.

Conclusion

As we navigate through the boundless horizons of technological innovation, it becomes increasingly clear that 3D Printing stands as a pivotal cornerstone in the narrative of progressive manufacturing and design. Emboldening creators with newfound freedoms and capabilities, this transformative technology is not just reshaping industries but also redefining what is possible in the realms of creation and production. Its harmonious blend of efficiency, creativity, and sustainability carves out a future where our environmental footprint is diminished, and the scope for innovation is boundless.

As we stand at the precipice of a new era, embracing the multifaceted advantages of 3D Printing seems not just prudent but essential, steering us towards a world where our visions are not confined to the digital screens but have the power to adorn the physical realm with grace, precision, and unparalleled brilliance. Let us venture forth into this promising future with 3D Printing as our steadfast companion, guiding us toward a landscape brimming with potential, innovation, and sustainable growth.

Admin

Admin

Leave A Reply

Your email address will not be published. Required fields are marked *